How does Allegro work?

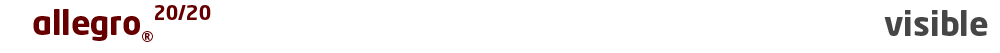

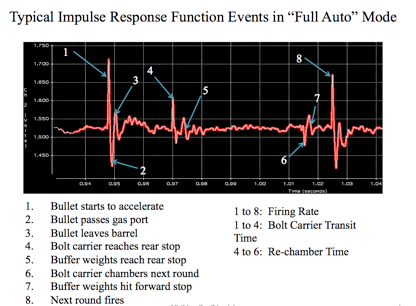

The Impulse Response Function (IRF) is key to any metric tied to performance of a weapon. The IRF is a waveform that plots acceleration vs. time when the weapon is fired. We place a RuBee tag that has a special accelerometer, with an amplifier, a processor and a high speed data link via a cable. We collect 1,000's of IRF waveforms from a weapon model. These are stored in our waveform database and analyzer. We use these waveforms to discover what happens when a weapon is overheated, about to jam, or needs a new spring. This gets translated into a state machine program that runs on a 4 bit, very low power processor and is known as a Key Performance Indicator (KPI). That KPI may be reported via a RuBee link in the field or through any RuBee network in an armory. Details and a flow chart are provided in whitepaper at bottom of this page.The figure below shows a tag in a grip and a typical Impulse Response Function. We provide many standard options for most weapons:

- Rounds Fired - a simple set of counters that keeps track of number of rounds fired though a barrel, lower mechanism, bolt. Good indicator of use and weapon age.

- Mean Kinetic Shots - calculates barrel temperature within +- 2C. The tag can warn an operator that temperature is too high and weapon is in danger of failing. Most accurate indicator of barrel status.

- Advanced KPI's - these are all weapon specific and can provide indicators for cleaning, and specific parts replacement.

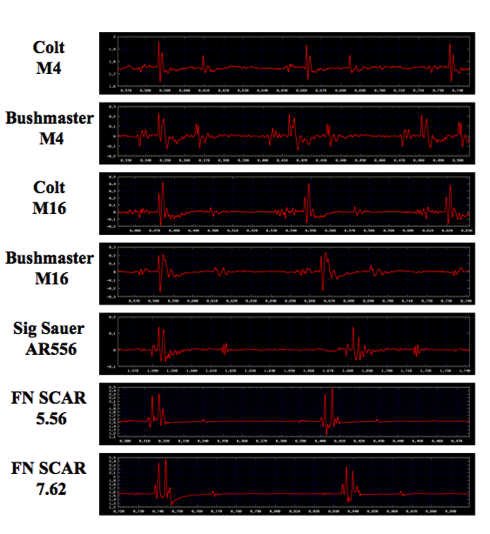

The IRF is an record of all the mechanical events that occur when a round is fired. A typical IRF is shown on left, with key mechanical events identified. It is important to emphasize that since the mechanics and mechanical events for different model weapons are different, we would also expect to see changes in IRF from one weapons platform to another. The IRF is unique for new weapon designs or models, but it is reassuring that it is typically the same for any given model or similar design. The IRF is the EKG of a weapon and can be used to diagnose almost any problem, warn a user of problems before it becomes too serious, and help optimize a new weapon design.

We attach a grip onto the weapon that has special circuitry and a battery plus sensor. The circuitry includes several custom integrated circuits, a low powered 4 bit processor, a NIST calibrated accelerometer with Li batteries that last 10 - 15 years. The grip includes an optional connector to capture high bandwidth IRF waveforms seen above. Most field grip units do not require the connector, since that is only used to calibrate and discover new KPI's for a weapon line or new model. The whitepaper at bottom of page explains in detail.

We attach a grip onto the weapon that has special circuitry and a battery plus sensor. The circuitry includes several custom integrated circuits, a low powered 4 bit processor, a NIST calibrated accelerometer with Li batteries that last 10 - 15 years. The grip includes an optional connector to capture high bandwidth IRF waveforms seen above. Most field grip units do not require the connector, since that is only used to calibrate and discover new KPI's for a weapon line or new model. The whitepaper at bottom of page explains in detail.

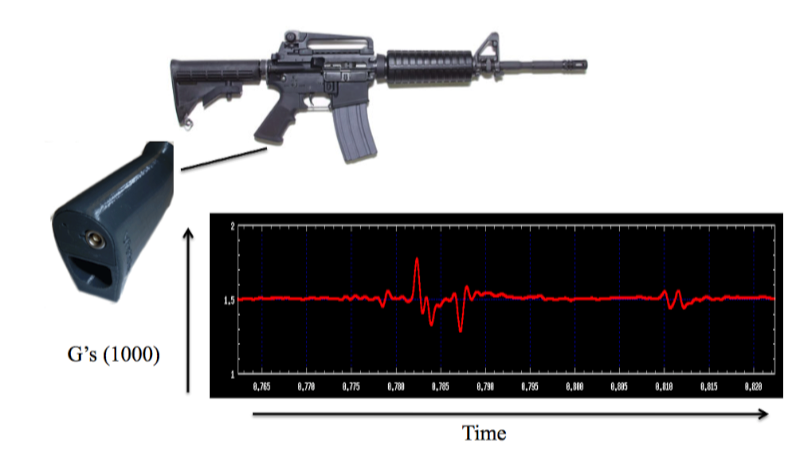

The WSC tag is programed and managed using a pRap, and data is read and transferred for long term storage via the pRap.

The tags may be read with any wireless RuBee link. The pRap seen on the left is RuBee enabled and can read all KPI's that are programed into any weapon tag. The same weapon can be automatically read on a RuBee enabled smart rack. This means can replace a weapon in any armory 20/20 systems and get read-out of use, and status and program maintenance cycles, based on that use.

Impulse Response Function Details

The Impulse Response Function is unique for any new weapon design or new model, but it is reassuring that it is typically the same for any given model or similar weapon design.

The IRF waveforms on right for a piston based SCAR and Sig AR 556 are quite different (both piston based carbines) from those of a direct impingement M4. However, The Colt and Bushmaster M4 (same weapon) but different manufacturers have near identical waveforms.

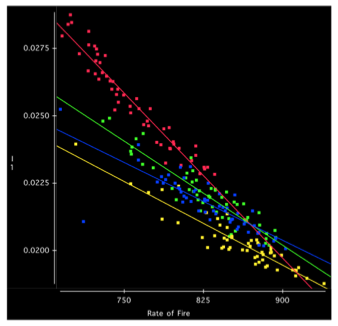

These results show clearly that we can measure interval I1 in a weapon that has been shot in single shot mode and predict the fully automatic mode rate of fire. Rate of fire is probably one the best indicators of general health of a weapon, and is one of the leading QC tests used to ensure a weapon functions correctly when manufactured. The red dots show an M4 that needs to be cleaned.

This means we can simply collect the I1 interval statistics in the weapons chip as a histogram, store it in memory for the last 30 rounds fired, and provide important diagnostic information by simply reporting the value of that interval, even if the weapon is only shot a few times in single shot mode. That also means that when the weapon is placed back on a rack after use we can predict its rate of fire no mater how the weapon has been used. If that predicted number is below 650 rounds per minute, the weapon likely needs to be cleaned or serviced. More examples of KPI's may be found in whitepaper below.

Whitepaper Summary

For detailed summary of of our entire weapons healthcare program read whitepaper:

The RuBee Wireless Weapon Tag, Firearms Calibration Protocol, Firearms Healthcare Program, and Firearms Diagnostics Laboratory, Visible Assets, Inc.